Home » Galvanising Service

Galvanizing is a process that involves coating steel or iron with a layer of zinc to protect against corrosion. This protective layer enhances the durability and lifespan of metal structures, making them suitable for outdoor and harsh environmental conditions.

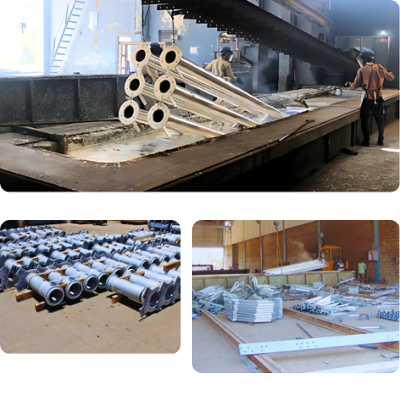

Shah Infra Towers offers hot-dip galvanizing services, which involves immersing cleaned steel components in molten zinc. This method provides a thick, uniform coating that effectively protects against corrosion.

Hot-dip galvanizing provides superior protection against corrosion compared to other methods such as painting or electroplating. The process creates a metallurgical bond between the zinc and steel, ensuring long-lasting protection that requires minimal maintenance.

We adhere to strict quality control standards during the galvanizing process. Our facility is ISO 9001:2015 certified, and we follow industry guidelines to ensure consistent coating thickness, adhesion, and overall quality of the galvanized products.

The lifespan of galvanized steel can vary based on environmental conditions, but it generally lasts 20 to 50 years without maintenance. The longevity of the coating depends on factors such as exposure to moisture and industrial pollutants.

The turnaround time for galvanizing services depends on the size and complexity of the components. Generally, our team strives to provide efficient service while maintaining high-quality standards. Please contact us for specific timelines based on your project needs.

To request a quote, please contact our sales team through our website or email with details of your project and the components you need galvanized. We will provide a customized quote based on your specifications.