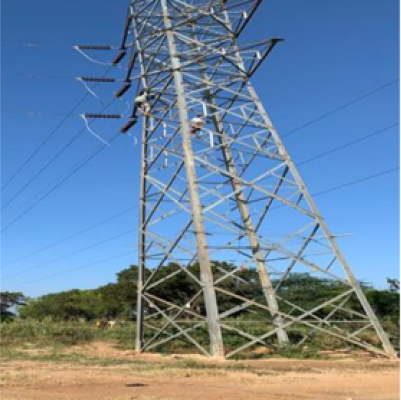

Shah Infra Towers Pvt. Ltd. focuses on delivering high-performance Transmission Line Towers, essential for ensuring reliable electricity distribution over long distances. Our state-of-the-art manufacturing facility employs advanced technology and machinery, allowing us to fabricate a diverse array of towers tailored to the unique requirements of the power transmission sector. We are committed to quality and innovation in every project we undertake.

33kV, 66kV, 110kV, 132kV, 220kV & 400kV – Single/Double/Multi Circuit

Shah Infra Towers provides a wide range of transmission line towers, designed . Our towers are engineered for optimal durability, superior performance, and tailored to meet the diverse needs of power utilities and corporations. All designs are in compliance with customer / utility specifications and other regulatory standards, ensuring long-lasting strength, reliable functionality, and a focus on practical design for seamless installation and maintenance.

33kV, 66kV, 110kV, 132kV, 220kV & 400kV – Single/Double/Multi Circuit

Shah Infra Towers provides a wide range of transmission line towers, designed . Our towers are engineered for optimal durability, superior performance, and tailored to meet the diverse needs of power utilities and corporations. All designs are in compliance with customer / utility specifications and other regulatory standards, ensuring long-lasting strength, reliable functionality, and a focus on practical design for seamless installation and maintenance.

to reduce costs and eliminate site rectifications.

60% of production is automated, for precision & scalability

with a capacity exceeding 60,000 MT annually.

For Seamless manufacturing and inventory control

from origin to finish, ensuring quality and compliance

To ensure zero material shortages at sites

Shah Infra Towers manufactures lattice towers, Our towers are designed for different voltage levels, ranging from 33kV to 400kV.

We use high-quality, durable steel for our transmission line towers, ensuring strength, corrosion resistance, and longevity. Our towers are hot-dip galvanized to provide additional protection against environmental factors like rust and weathering.

Yes, we offer customized solutions based on client requirements, including specific designs for different terrains, environmental conditions, and voltage levels. Our engineering team works closely with clients to deliver tailored solutions.

Shah Infra Towers adheres to strict quality control procedures at every stage of the manufacturing process. We are certified under ISO 9001:2015, ISO 14001:2015, and ISO 45001:2018, ensuring that our products meet international standards for quality, environmental management, and workplace safety.

You can contact our sales team via our website or email with your project specifications. We will provide a customized quote based on your requirements and guide you through the ordering process.