Home » Solar Support Structures

W6 & W8 series of Wide flange steel beams (piers, steel piles)

Shah Infra Towers is one of the solar beams manufacturing units in Davangere, Karnataka State, India. It has entire range (W6 & W8 series) of Wide flange steel beams (piers, steel piles) with the capacity of around 48,000 MT annually. Shah Infra has backward integration with the Rolling Mills for converting steel billets into angles, beams, channels etc. Backward integration has put Shah Infra into an advantageous position where quality and delivery timeline are under control and enabling Shah Infra for the lowest possible manufacturing and supply lead time.

33kV, 66kV, 110kV, 132kV, 220kV & 400kV – Single/Double/Multi Circuit

Shah Infra Towers provides a wide range of transmission line towers, designed . Our towers are engineered for optimal durability, superior performance, and tailored to meet the diverse needs of power utilities and corporations. All designs are in compliance with customer / utility specifications and other regulatory standards, ensuring long-lasting strength, reliable functionality, and a focus on practical design for seamless installation and maintenance.

W6 & W8 series of Wide flange steel beams (piers, steel piles)

Shah Infra Towers is one of the solar beams manufacturing units in Davangere, Karnataka State, India. It has entire range (W6 & W8 series) of Wide flange steel beams (piers, steel piles) with the capacity of around 48,000 MT annually. Shah Infra has backward integration with the Rolling Mills for converting steel billets into angles, beams, channels etc. Backward integration has put Shah Infra into an advantageous position where quality and delivery timeline are under control and enabling Shah Infra for the lowest possible manufacturing and supply lead time.

W6 & W8 series of Wide flange steel beams (piers, steel piles)

Shah Infra Towers is one of the solar beams manufacturing units in Davangere, Karnataka State, India. It has entire range (W6 & W8 series) of Wide flange steel beams (piers, steel piles) with the capacity of around 48,000 MT annually. Shah Infra has backward integration with the Rolling Mills for converting steel billets into angles, beams, channels etc. Backward integration has put Shah Infra into an advantageous position where quality and delivery timeline are under control and enabling Shah Infra for the lowest possible manufacturing and supply lead time.

33kV, 66kV, 110kV, 132kV, 220kV & 400kV – Single/Double/Multi Circuit

Shah Infra Towers provides a wide range of transmission line towers, designed . Our towers are engineered for optimal durability, superior performance, and tailored to meet the diverse needs of power utilities and corporations. All designs are in compliance with customer / utility specifications and other regulatory standards, ensuring long-lasting strength, reliable functionality, and a focus on practical design for seamless installation and maintenance.

W6 & W8 series of Wide flange steel beams (piers, steel piles)

Shah Infra Towers is one of the solar beams manufacturing units in Davangere, Karnataka State, India. It has entire range (W6 & W8 series) of Wide flange steel beams (piers, steel piles) with the capacity of around 48,000 MT annually. Shah Infra has backward integration with the Rolling Mills for converting steel billets into angles, beams, channels etc. Backward integration has put Shah Infra into an advantageous position where quality and delivery timeline are under control and enabling Shah Infra for the lowest possible manufacturing and supply lead time.

to reduce costs and eliminate site rectifications.

60% of production is automated, for precision & scalability

with a capacity exceeding 60,000 MT annually.

For Seamless manufacturing and inventory control

from origin to finish, ensuring quality and compliance

To ensure zero material shortages at sites

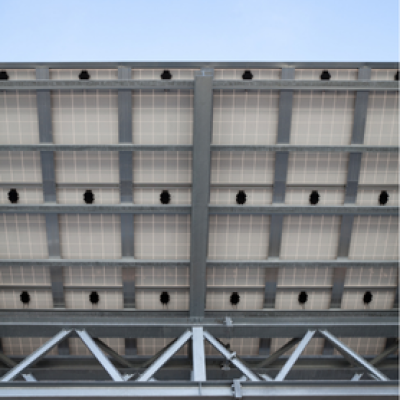

Solar support structures are specially designed frameworks used to mount solar panels securely in place. They ensure optimal positioning of the panels to maximize sunlight exposure, enhance energy efficiency, and withstand environmental conditions.

Shah Infra Towers manufactures a wide range of solar support structures, including fixed tilt structures, adjustable tilt structures, and solar trackers. These are suitable for various terrains, from flat to uneven ground, and can be customized to meet project-specific needs.

Solar beams are structural components used to support solar panels in solar energy installations. They provide a stable framework that ensures the proper alignment and positioning of panels to maximize sunlight exposure and energy generation.

When choosing a solar support structure, factors such as site location, climate, wind loads, panel orientation, and project size should be considered. Our team offers expert guidance to help you select the best structure for your specific project.

We adhere to strict quality control processes throughout the manufacturing of solar beams. Our facility is certified under ISO 9001:2015, and we conduct rigorous testing to ensure compliance with industry standards for strength, load-bearing capacity, and durability.

Yes, we offer customizable solar beams tailored to meet specific project requirements. Our engineering team works closely with clients to design and manufacture beams that accommodate unique site conditions and installation needs.

Yes, we offer fully customizable solutions. Our engineering team works closely with clients to design and manufacture support structures tailored to specific site conditions, installation requirements, and project scales.

Hot-dip galvanizing offers superior protection against rust and corrosion, particularly in outdoor environments. This process extends the life of the structure, reduces maintenance costs, and ensures consistent performance over decades.