Home » Manufacturing Facility

Shah Infra Towers is equipped with a comprehensive machinery setup designed for diverse industrial tasks. Our facility includes:

Power press (10 to 200 Tons)

Hydro Machines for shearing, punching, notching, and stamping, with capacities ranging from 70MT to 120MT.

Plate Shearing Machine (2000x16mm) and Radial Drilling Machines (25-40mm) for precise cutting and drilling.

E.O.T Cranes (2-3 tons) and Power Press Machines (10-100 tons) for efficient material handling and high-precision stamping.

High speed CNC Punching, Marking & Shearing Line for angles, handling materials from 40x40x3mm to 150x150x16mm angles

7-Tank Galvanizing Setup with all the necessary machinery for superior metal protection.

This advanced setup allows Shah Infra Towers to deliver projects with efficiency, precision, and the highest standards of quality.

Our state-of-the-art facility in equipped with a galvanizing bath measuring an impressive 10m Length x 1m Width x 1.6m Depth This extensive setup allows us to achieve a monthly production capacity of 5,000 metric tonnes, with our current output reaching 4,500 metric tonnes per month. This capacity underscores our capability to meet the demands of large-scale projects while maintaining the highest quality standards.

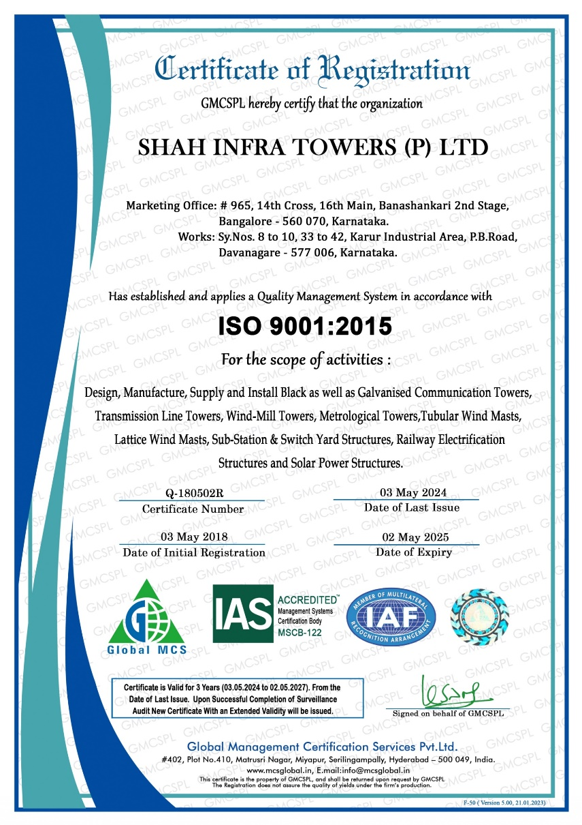

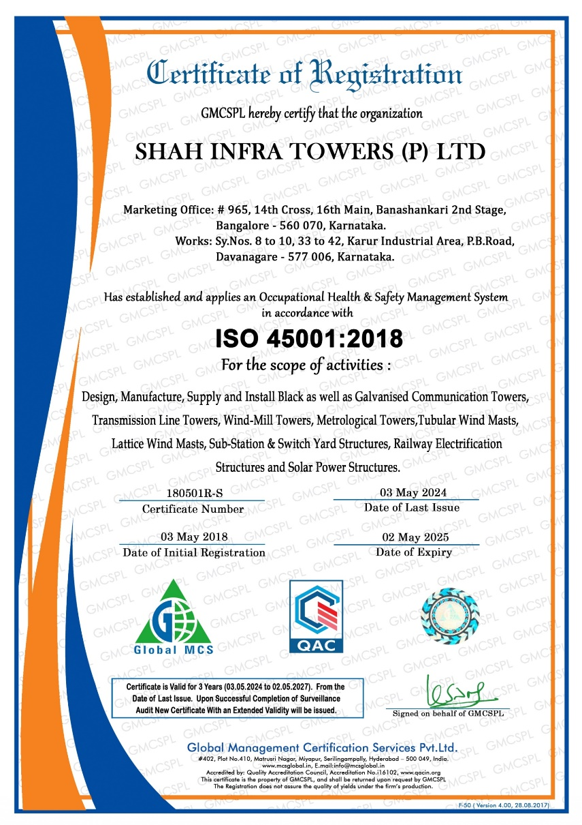

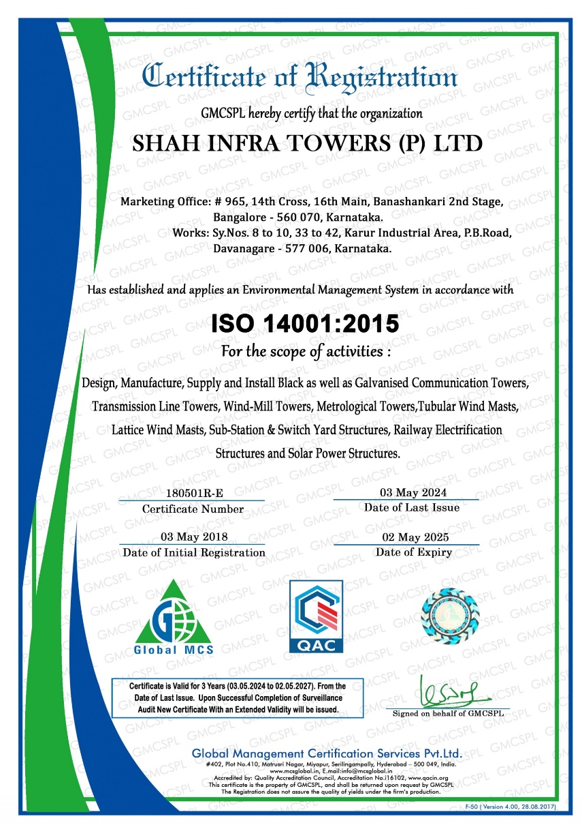

Shah Infra Towers is committed to delivering the highest standards of quality through rigorous testing and precision engineering. Our quality assurance processes are supported by state-of-the-art testing equipment, ensuring every product meets stringent industry standards.

•Universal Testing Machine (600 KN) for strength testing.

•Rockwell Hardness Tester for measuring material hardness.

•Vernier Calipers and Micrometers for precise dimensional measurements.

•Coat Meters/Elcometers for accurate coating thickness assessments.

•Digital pH Meter and Weighing Scale for chemical and weight accuracy.

Systematic Storage with clearly designated areas for different product categories,

enabling quick access and inventory management.

Quality Inspection before dispatch to verify that all products meet the required

standards.

Safe Handling with trained personnel and appropriate equipment to prevent damage

during storage and loading.

Efficient Dispatch Processes ensuring timely and accurate delivery to our clients,

with tracking systems in place for real-time updates.